From Wikipedia, the free encyclopedia, Natamycin (INN), also known as pimaricin and sometimes sold as Natacyn, is a naturally occurring antifungal agent produced during fermentation by the bacterium Streptomyces natalensis, commonly found in soil. Natamycin has a very low solubility in water; however, natamycin is effective at very low levels. There is an MIC (minimum inhibitory concentration) of less than 10 ppm for most molds. Natamycin is classified as a macrolide polyene antifungal and, as a drug, is used to treat fungal keratitis. It is especially effective against Aspergillus and Fusarium corneal infections. Other common members of the polyene macrolide antifungal family are amphotericin B, nystatin, and filipin. Natamycin is also used in the food industry as a "natural" preservative.

|

|

|---|---|

| Systematic (IUPAC) name | |

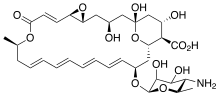

| (1R,3S,5R,7R,8E,12R,14E,16E,18E,20E,22R,24S,25R,26S)-22-[(3-amino-3,6-dideoxy-D-mannopyranosyl)oxy]-1,3,26-trihydroxy-12-methyl-10-oxo-6,11,28-trioxatricyclo[22.3.1.05,7]octacosa-8,14,16,18,20-pentaene-25-carboxylic acid | |

| Clinical data | |

| AHFS/Drugs.com | monograph |

| Pregnancy cat. | ? |

| Legal status | ? |

| Identifiers | |

| CAS number | 7681-93-8 |

| ATC code | A01AB10 A07AA03, D01AA02, G01AA02, S01AA10 |

| PubChem | CID 441382 |

| DrugBank | DB00826 |

| ChemSpider | 10468784 |

| UNII | 8O0C852CPO |

| KEGG | C08073 |

| ChEMBL | CHEMBL1200656 |

| Chemical data | |

| Formula | C33H47NO13 |

| Mol. mass | 665.725 g/mol |

| |

|

Uses

In foods

Natamycin has been used for decades in the food industry as a hurdle to fungal outgrowth in dairy products, meats, and other foods. Potential advantages for the usage of natamycin might include the replacement of traditional chemical preservatives, a neutral flavor impact, and less dependence on pH for efficacy, as is common with chemical preservatives. It can be applied in a variety of ways: as an aqueous suspension (such as mixed into a brine) that is sprayed on the product or that the product is dipped into, or in powdered form (along with an anticaking agent such as cellulose) sprinkled on or mixed into the product. While not currently approved for use on meats in the United States, some countries allow natamycin to be applied to the surface of dry and fermented sausages to prevent mold growth on the casing. Also, natamycin is approved for various dairy applications in the United States. More specifically, natamycin is commonly used in products such as cottage cheese, sour cream, yogurt and packaged salad mixes.As a food additive, it has E number E235. Throughout the European Union, it is only approved as a surface preservative for certain cheese and dried sausage products. It must not be detectable 5 mm below the rind. The EU Scientific Committee on Food (SCF) states on the usage of Natamycin: "However, in view of the general principle with regard to the undesirability of using antibiotics in foodstuffs the Committee is strongly opposed to proposals for further food uses of natamycin such as use on ham and wine and other beverages." (SCF, 1979)[1]

Medical

Natamycin is used to treat fungal infections, including Candida, Aspergillus, Cephalosporium, Fusarium and Penicillium. It is applied as a cream, in eyedrops, or (for oral infections) in a lozenge. Natamycin shows negligible absorption into the body when administered in these ways. When taken orally, little or none is absorbed from the gastrointestinal tract, making it inappropriate for systemic infections.[2]Safety

Natamycin does not have acute toxicity. In animal studies, the lowest LD50 found was 450 mg/kg. In rats, the LD50 is ≥2300 mg/kg, and doses of 500 mg/kg/day over 2 years caused no detectable differences in survival rate, growth, or incidence of tumors. The metabolites of natamycin also lack toxicity. The breakdown products of natamycin under various storage conditions may have a lower LD50 than natamycin, but in all cases the numbers are quite high. In humans, a dose of 500 mg/kg/day repeated over multiple days caused nausea, vomiting, and diarrhea.[3]There is no evidence that natamycin, at either pharmacological levels or levels encountered as a food additive, can harm normal intestinal flora, but definitive research may not be available.[3]

The European Food Safety Authority (EFSA) has concluded that the use of natamycin as a food additive has no relevant risk for the development of resistant fungi.[4]

References

- ^ http://europa.eu.int/comm/health/ph/others/antimicrob_resist/am_03_en.pdf[dead link]

- ^ Sweetman, S. (2004). Martindale: The Complete Drug Reference

- ^ a b Mattia, A. et al. Safety evaluation of certain food additives and contaminants: natamicin (pimaricin). WHO Food Additives Series #48.

- ^ Scientific Opinion on the use of natamycin (E 235) as a food additive